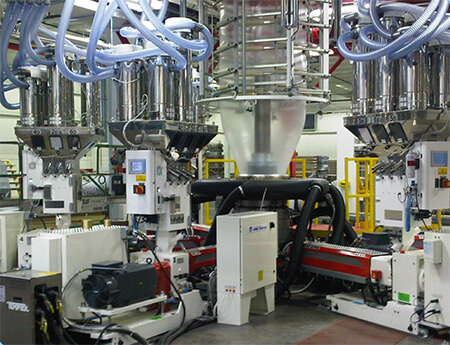

Gravimetric Blending & Dosing System

Plastech supplies Syncro, Italy make of automation products including Gravimetric Batch Blenders, Automatic Thickness Measurement & Control, IBC Control System & Supervisory Controls.

At Plastech, the gain-in-weight batch blender combines many features such as easy handling, accuracy in operation, blending multiple components in sequence and simple cleaning of the batch.

The new design of the slide valves and see through construction are meant to assist the user. The mixing hopper itself, works as a gravimetric weighing hopper in a ‘loss in weight’ process.

For special requirements, a combination of both batch and continuous dosing principle is also possible.

Principle of Operation

- Gain-in-weight batch blender.

- Each ingredient is metered in sequence by slide gate valves in the weighing hopper mounted on two load cells.

- Once the pre-set batch weight has been reached, the load cell sends a signal and the batch is unloaded into the weighing mixing chamber combining the batch and the loss in weight technology.

Main Features

- Gravimetric extrusion throughout

- Control accuracy

- Gravimetric dosing accuracy

- Good mixing

- Modularity

- Easy cleaning-product changeover

- Each component can be switched to any ratio by small adaptation

- Adaptability to convey loaders

- Easy access to components

SmartdraYn is the PATENTED innovative automatic draining system available on MYbatch batch blender

- Faster changeover

- Self cleaning

- Minimized waste

- Material traceability

- Operator safety and health improvement

Retrofittable for Upgradation & Modernisation on Old Blown Film Extrusion Lines

- Single component system for pre-blended materials

- Complete system with comprehensive batch blending