PVC Pipe Extrusion Lines

PVC Pipe Extrusion Lines

Our Pipe extrusion lines are crafted with superior brand components to ensure stability, optimum performance and fluid efficiency for a wide range of utility.

The standard range covers capacity up to 350 kg/hr & popular pipe size range from 14 mm to 200 mm pipe outer diameters.

However, our flexible approach allows our customers to have unique and custom pipe extrusion solutions tailored to their needs. These can be supplied and purchased as a standalone requirement thus you can upgrade your existing production lines.

Key Features

- Two piece barrel construction

- Front barrel with HSS sleeve for long service life & low replacement cost

- PLC operating controls as standard

- Tungsten carbide coating provided on twin screws for high wear resistance (optional)

- Field proven reliable designs

- 18:1 to 28:1 L/D ratio models

- Output 170 kg/hr to 350 kg/hr for UPVC pipes

- Chrome plated on flow surfaces of die heads

General Applications

- Construction piping for electricals, plumbing, drainage & sewerage

- Pressure and non-pressure applications

- Potable water distribution systems

- Agriculture & irrigation pipes

- Industrial fluids transportation pipe lines

- Water & waste-water treatment plants

- Chemical transportation pipe lines

Applications

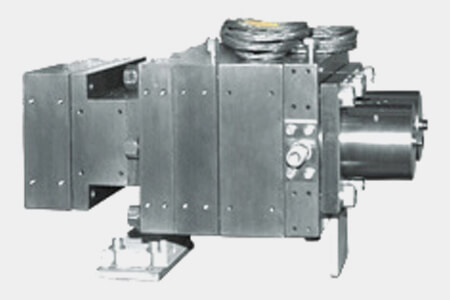

Extruder

| PM-TS Models for PVC Pipe Extruders | ||||||

| Models | PM-TS-110 | PM-TS-170 | PM-TS-200 | PM-TS-250 | PM-TS-350 | |

| Screw Diameter | mm | 52 | 65 | 65 | 65 | 71 |

| Screw Speed | rpm | 5-50 | 4-45 | 5-53 | 5-53 | 5-53 |

| L/D Ratio | – | 20:01 | 18:01 | 18:01 | 22:01 | 28:01 |

| Main Motor | kW | 11 | 15 | 22 | 22 | 30 |

| Max. Output | kg/hr | 100-110 | 150-170 | 180-200 | 230-250 | 330-350 |

| Pipe Range (Single Die) | mm | 20-110 | 20-200 | 20-200 | 63-250 | 110-315 |

| Pipe Range (Twin Die) | mm | 19-50 | 19-50 | 19-50 | 20-110 | 20-110 |

| USE with Dual Pipe Strand Models | – | Available | Available | Available | Available | |

** (We offer single pipe, twin pipe & dual pipe extrusion system as well.)

Die Heads | PVC Processing

Plastech offers field proven reliable design for die heads for variety of applications and considering optimum processing performance.

Advantages

- Reliable designs for wide range of pipe sizes and thicknesses.

- Uniform melt distribution throughout the entire pipe.

- Twin & Dual Pipe die heads for higher outputs in smaller diameters.

- Configurations for extruder’s utilization up to 80-100% even in entire range

| Models for Die heads PVC | ||||||

| Models | PM-63 | PM-110 | PM-110HV | PM-200LV | PM-200HV | |

| Pipe Range | mm | 20-63 | 20-110 | 20-110 | 63-200 | 63-200 |

| Output Capacity up to** | Kg/hr | 100 | 200 | 250 | 250 | 320 |

| Dual Pipe Strand Models | Available | Available | Available | Available | Available | |

Vacuum Sizing Tanks

Vacuum sizing is the most widely used arrangement for PVC pipe production. We offer vacuum sizing tanks in stainless-steel highest-grade SS-304 for long service life & optimum results. Our vacuum sizing tanks designs are suitable for several line requirements.

- Effective cooling design provided to ensure high production of pipes

- Self-cleaning spray nozzles are used

- Accurate vacuum control circuit, water level control circuit & automatic temperature control provided

- Axial movement provided for easy handling

- Manual slide rail arrangement for axial and transverse movement of the tank for easy pipe center alignment

- Imported filters for inline cleaning

| PM-VST Models for Vaccum Sizing Tanks | |||

| Models | PM-VST-110 | PM-VST-200 | |

| Pipe size Range Single-Pipe | mm | 20-110 | 20-200 |

| Length of cooling | mm | 6000 | 6000 |

| DUAL TANKS * | with CD-400 mm | With CD-500 mm | |

| Dual Pipe Stand Models | Available | Available | |

| *Dual pipe strand tanks are offered for Dual pipe extrusion | |||

Traction Unit

- Up to 2 & 4 track to suit pipe diameters

- Wide range of line speeds possible using SERVO designs

- Track adjustment by pneumatic control

- Direct Geared motor on individual tracks

- Counter balance pressure to balance track weight for thin pipes

- Encoder for length measurement & feedback arrangement offered optionally

- Easy accessibility for maintenance of all components

- Dual twin-track traction units for dual pipe extrusion line

- Servo design (optional)

- Thick-thin provision (optional)

| PM-VST Models for Caterpiller Models | |||

| Models | PM-TTU-110 | PM-TTU-200 | |

| Pipe Range | mm | 16-110 | 20-200 |

| No. of Tracks | Nos. | 2 | 2 |

| Max. Line Speed | Mtrs./Min. | 15 (or 20) | 10 (or 15) |

| Minimum Line speed | with Std. Drive | 1.2 (or 1.6) | 0.8 (or 1.2) |

| Minimum Line speed | mpm/with *servo drive option | 0.15 (or 0.2) | 0.1 (or 0.15) |

| Contact Length | mm | 800 | 1200 |

| Dual Pipe Strand Models | Available | Available | |

| *Servo option is available on additional charge | |||

Cutting Unit

Tube Cutting Unit (TCU)

- Rotating circular saw designs

- Pneumatically operated carriage movement

- Clamping force adjustable depending upon the wall-thickness of the pipe

- Swarf removal system optional

- Trolley movement on linear bearings for long service life

- Special guillotine design cutter available for PPR pipes

- Dual cutter for dual pipe extrusion line

- Digital counter to measure length & actuation of cutting

- PLC based controls available optionally

| PMC Saw Cutter Models | |||

| Models | Unit | PMC-110 | PMC-200 |

| Pipe Range | mm | 20-110 | 20-200 |

| Cutting Speed (Max.) | Mtrs/Min. | 18 | 10 |

| Clamping From | – | Top | Top |

| Dual Pipe Stand Models | Available | Available | |

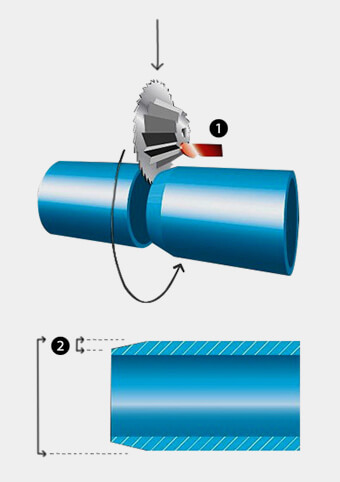

Planetary Cutting Unit (PCU)

- Planetary/rotary design cutters available for pipe size range 32 mm onwards

- Inline chamfering is available on these cutters

- Universal clamping system for self centering design

- Cutting and chamfering simultaneously

- Pipe dust and chips suction arrangement

| PM-PC-110PVC | PM-PC-200PVC | ||

| Pipe Range | mm | 16-110 | 63-200 |

| Line Speed (Max.) | Mtrs/Min. | 25 | 12 |

| Max. Pipe Thickness | mm | 20 | 28 |

Pipe Tilting Unit

- Pneumatically operated

- Easy receiving of pipes

- We also provide inline belling units

- Two limit switch actuation – one for pipe cutter feedback and other for tilting the pipe