Offline Recycling Systems - OMEGA

Omega

With increasing competition there is focus of industry to enhance efficiency of operations and become competitive through optimized economics. Factory in-house waste has been a significant cost of operations in Blown film extrusion. Gone are the days when the in-house factory waste was considered a scrap and recycled into degraded pellets for use in second stage plastic applications. Now processors try and recycle the in-house factory waste into high quality pellets for refeeding into the same application. Here the OMEGA offers a complete solution to recycle in-house factory waste (unprinted or printed) into high quality near virgin pellets and re-feed into same extruder. This greatly improves economics & efficiency of operations.

Every Reason to Choose Omega:

- Minimal power consumption & the superior output/kW installed power in the market. It lowers running costs and improves return on investment.

- Low shear, minimum process dwell time and the absolute minimal material degradation. It means one can recycle all the scrap material into high quality pellets. It further reduces the material costs.

- Integrated single shaft, low speed shredder results in no additional rotor cooling thereby reducing running costs and maintenance.

- Being the smallest footprint extrusion machine in the market, it requires minimal floor space thus freeing up valuable space for other applications.

- SY-View HMI Control – needs no special operators to run other plant equipment. This reduces personnel overheads.

SST Technology Ensures:

- Minimal power consumption

- Low shear

- Minimum process dwell time

- Absolute minimal material degradation

- The Highest output/kW installed power in the market

- Integrated single shaft, low speed shredder

- Can recycle nearly any form of waste material

- Patented shredder screen design

- Automated start-up, running and shut down control

- Can be supplied non-vented or vented with a single or double vent

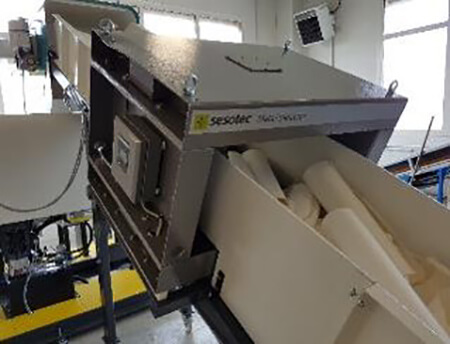

- Multiple feed systems available, including elevator with integrated metal detector, roll-feed or trim basket feed

- Available in air cooled (up to the Omega 180) and water cooled designs

- Select from manual, continuous, back flush or full automatic screen changers

- SY-View HMI control

- The smallest footprint extrusion machine available on the market

Accessories