Film Thickness Controls

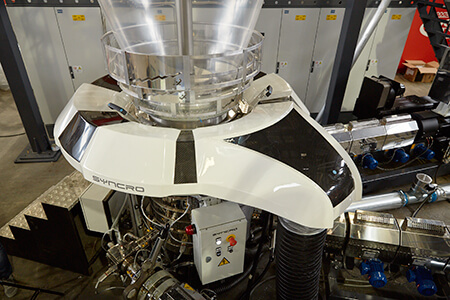

Plastech supplies Syncro, Italy make of automation products including Gravimetric Batch Blenders, Automatic Thickness Measurement & Control, IBC Control System & Supervisory Controls.

The new improvised and innovative model -TYPHOON Air Ring is iconic and one of its kind for an air ring with auto profile control.

The thickness measuring system is integrated into the supervision software, it supplies TYPHOON with the measurement profiles. To measure a point having a thickness higher than the set tolerance, the stepper motor decreases the air flow in the corresponding segment, thus reducing the film thickness proportionately. Likewise, when measuring a point with a thickness lower than the tolerance, the air flow is increases in order to increase the film thickness.

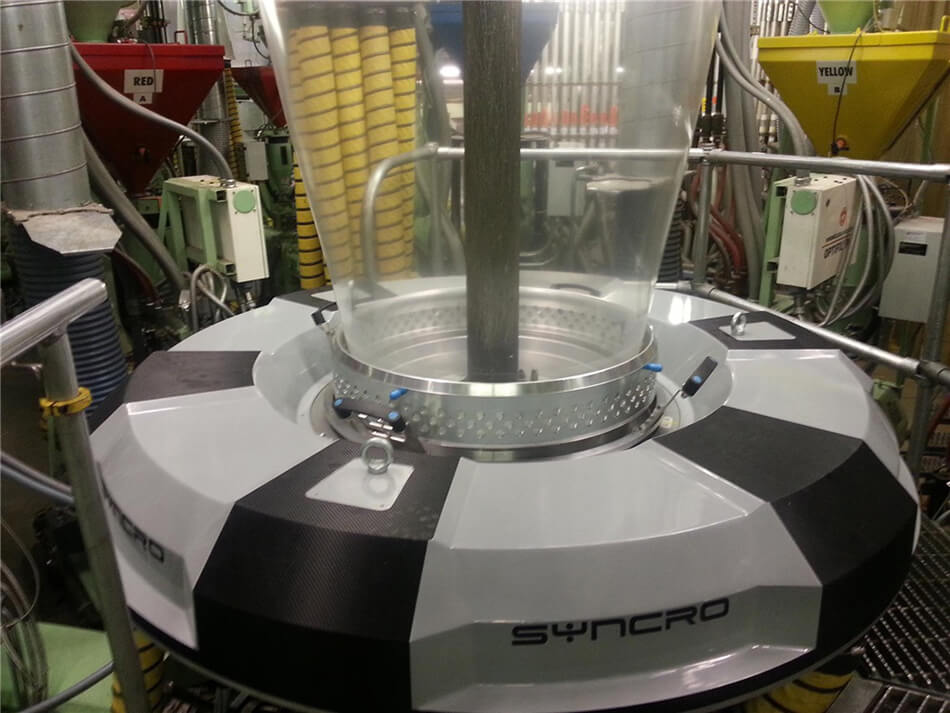

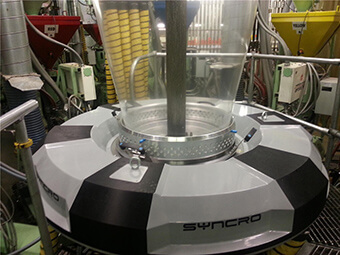

It is available with a single entrance carbon fibre chamber.

Characteristics

- Can be upgraded to automatic control for future

- Available in 6 sizes up to a die diameter of 2,500 mm

- Adjustable lip-set

- 6/8/10/12 air inlets

- Interchangeable lip-set

Advantages of Carbon Fibre Chamber

- Two carbon fibre skins with a sandwiched insulation layer in the middle for «zero» moisture.

- Booster stabilizer available for better bubble stability and higher output.

- Relatively light weight for easy handling.

Manifold

SYNCRO manifold, for aluminium multi entrance chamber is the ideal solution to connect chiller air pipe to multi air inlets to simplify the installation.

Installation

The measurement systems ends the profile data to the software which calculates and manages the positioning of the actuators.

The actuators control segmented air flows that is modified following the profile to be adjusted. This air flow influences the melt temperature and in turn the film thickness during film blowing step.

FLYER is now available with Tech 2.0 for combined power of motorized and thermal correction which delivers upto 75% improvement in thickness distribution compared to standard systems which delivers upto 50% improvement only.

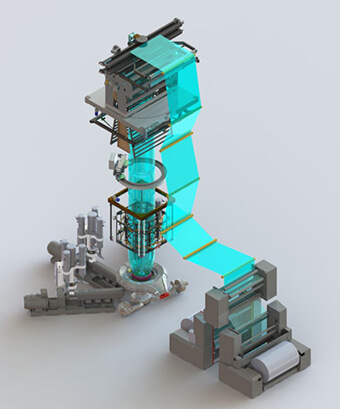

Elevators lift the automatic upper four lip air ring almost double the line throughout and also improves the physical proprieties of the film. (Tear, haze, elongation and especially dart drop)

When FLYER is raised to the upper position, the bubble expansion is greater. This provides efficient cooling over a large surface area. FLYER provides segmented airflow to the localized areas around the blown film bubble through the air ring. It also stabilizes the film exit due to the fourth special downward lip. This automatic thickness improvement system offers simplicity and state-of-the-art visualization thereby also giving the highest operational reliability.

Principle of Operation

- Easy installation

- Carbon fibre chamber with single air entrance

- Two carbon fibre skins with a sandwiched insulation layer in the middle for «zero» moisture

- Booster stabiliser for better bubble stability and higher output

- New lifting system managed by Syntrol for repeatable positioning via the product recipe

Technology Tech2.0 Patented

FLYER is now available with Tech 2.0 for a 75% improvement in profile control.

The innovative and patented Tech 2.0 enhances the volume and heater control to improve profile control.

- Short time to reduce the original profile deviation

- Significant reduction of scrap

- Increased level of planarity

- Regulation technology can be selected independently

- Up to 80% reduction of starting profile deviation at 2σ

SYNTROL GAUGE auto profile control is fluid and futuristic giving the best of results. It suitable for the use on blown film lines for thickness measurement and control.

It can be interfaced on to an OEM die with thermal cartridge heaters to modify the die lip opening/closing according to target thickness. It can be supplied along with the quenching auto flex lip control or it can be interfaced to automatic air rings with internal cartridge heaters installed to control the gauge via the air temperature set by the target thickness.

Plastech’s SYNTROL GAUGE has an auto die system to control automatically the thermal bolts used on flat dies to regulate the film/sheet thickness via mechanical manipulation of the flat die lip. Due to the smart control, special die mapping will allow the system to compensate for material neck-in, neck-out and bump profiling to achieve the tightest gauge control.

SYNTROL GAUGE is based on commercial modular PLC electronics and ensures simple, practical operation by providing the operator with all the information required to operate the system using touch screen HMI on board. In a blown film application, it can be controlled and connected easily to any of the Plastech gauging systems.