Film Thickness Measurement

Plastech supplies Syncro, Italy make of automation products including Gravimetric Batch Blenders, Automatic Thickness Measurement & Control, IBC Control System & Supervisory Controls.

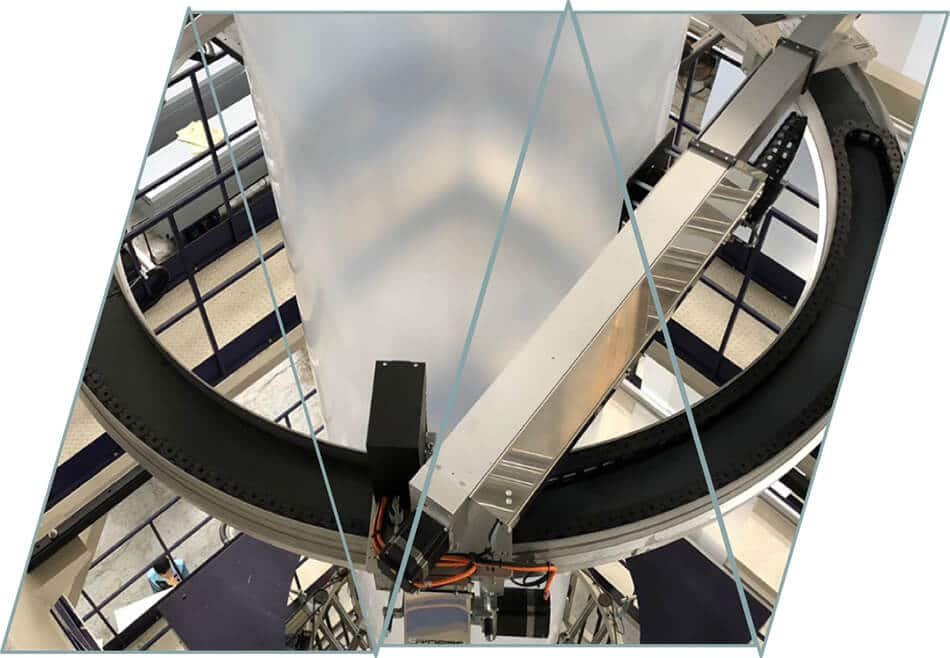

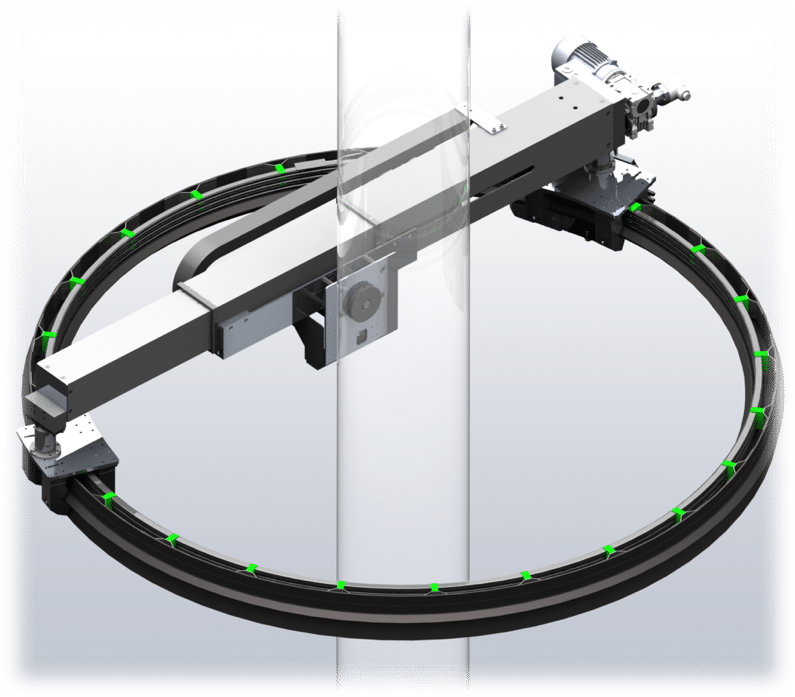

Resting on two sliding carriages turning around the extruded bubble, Skymex is better than any other equivalent thickness measurement system. The accurate thickness measurement system optimizes the four basic requirements – toughness; absence of vibrations; a wide range of radial measures and nil radial overhang between the carriages. Measuring sensors available in the standard version.

Other optional technologies (optical interferometry, multilayer, etc.) can be supplied upon request with prior feasibility assessment.

Principle of Operation

- Capacitive technology

- Ideal for non-barrier film

- 360° rotating system

- 360° encoder band

- Belt free motion

- Ultrasonic distance sensor

- Triple stage telescopic arm

- Available up to 14 meter lay flat

Sensors

New non-contact sensor for rotating measurement systems – no marks on your film.

Sensor made of porous material generating a constant air cushion which will keep a stable gap between bubble and sensor.

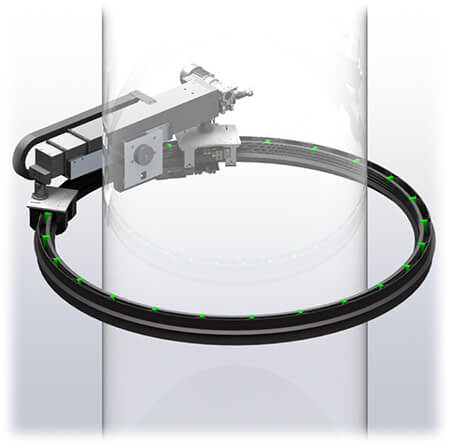

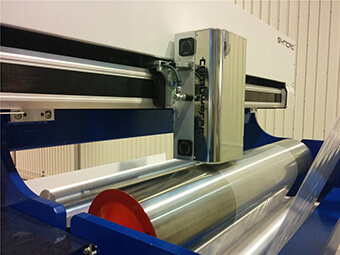

EASYMEX is based on capacitive technology and provides a continuous thickness measurement. It can be installed either stand alone on the collapsing frame or on an oscillating ring connected to an auto profile control.

It is available in both contact and non-contact versions for materials considered sticky and/or delicate.

Characteristics

- Capacitive technology

- Ideal for non-barrier film

- Oscillating or rotating system

- 360° Encoder band

- Belt free motion

- Ultrasonic distance sensor

- Double stage telescopic arm

- Available up to 2,800 mm bubble diameter

- Limited risk of damage leading to a bubble break

Other Sensors

Plastech’s COMBYSCAN is a patented measuring system based on non-contact inductive/capacitive technology. The new sensor COMBY is composed of an Inductive/capacitive sensor which allows the measurement of either sheet and/or film thickness using a cylinder as a datum. COMBY uses inductive technology to measure the distance between the sensor and the cylinder.

The second capacitive sensor measures the dielectric of the material. This provides a more accurate thickness value. COMBYSCAN is used on flat die lines or blown film lines.

OPTYMEX non-contact gauging system is based on NIR reflex technology for blown film.

OPTYMEX provides a continuous measuring of material thickness. Installed on an oscillating ring it can refresh the profile every 2-3 minutes, not influenced by the haul off speed.

The RAYXSCAN uses an x-ray beam transmission for homogeneous material to be measured. To measure the thickness in mm or the weight shown in [g/m²]. An x-ray source is situated in a housing, while another housing contains the receiver and is positioned opposite the transmitter at a set distance.

The film runs between the transmitter and receiver. The two housings containing the transmitter and receiver run across the web width. When a homogeneous layer of material is positioned between the transmitter and receiver, part of the energy transmitting to the receiver is absorbed by the material. The energy measured by the receiver is attenuated compared to the energy without the material.It allows the physical proprieties of the material to calculate the ratio between the attenuation and the material weight.

RayXscan is not considered a radioactive source because the tension on the node is lower than 5 kV, for this reason this scanner does not need to follow the radio protection regulations and hence a safety certificate is not necessary.