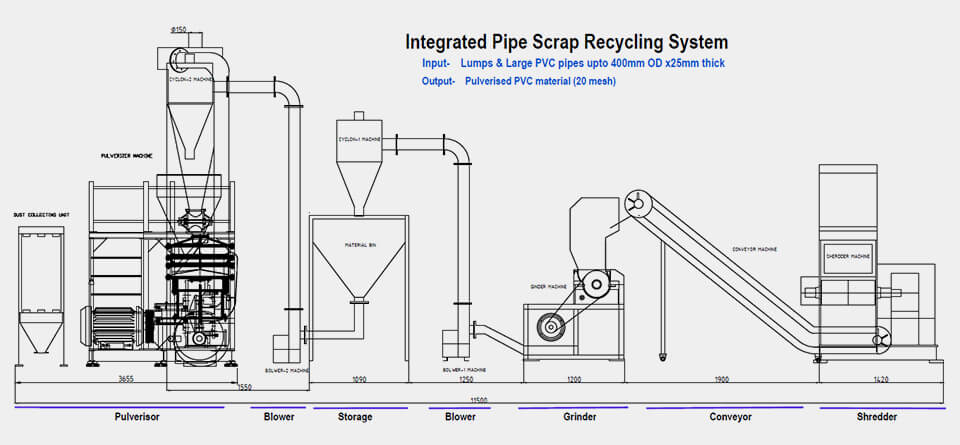

Shredder, Grinder & Pulveriser

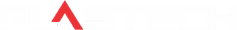

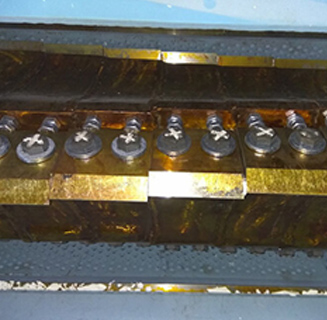

Pipe Waste Shredder

- 40 HP model

- Single shaft shredder

- Heavy duty design

- Up to 400 mm PVC pipe, 25 mm thickness & 500 mm length can be directly fed into the shredder

- Lumps & start-up pipe waste can be fed directly

Main Features

| Sr.No. | Models | Output | Motor Capacity | Cutting Chamber | Screen Hole Size |

| 1 | PM-SHREDD 600 | 250 to 300 kg/hr | 40 HP | 600 x 400 mm | 40 mm |

| 2 | PM-SHREDD 800 | 500 kg/hr | 55 HP | 800 x 600 mm | 40 mm |

| *Output depends upon type of materials, thickness etc. | |||||

| *Above specification of drive are for general purpose applications. | |||||

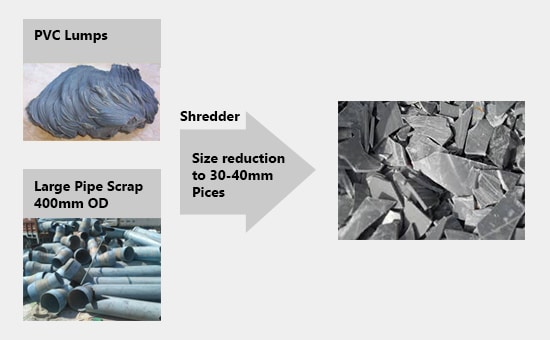

PVC Scrap Grinders (Size Reduction)

- Low speed high torque

- Quality workmanship

- Segmented blade design

- Long blade service life

Specifications

| Sr.No. | Models | Output | Motor Capacity | Cutting Chamber | Screen Hole Size |

| 1 | PM-GRINDE 400 | 130 to 150 kg/hr | 12 HP | 400 x 300 mm | 8 mm / 10 mm |

| 2 | PM-GRINDE 500 | 175 to 200 kg/hr | 20 HP | 500 x 400 mm | 8 mm / 10 mm |

| 3 | PM-GRINDE 600 | 225 to 250 kg/hr | 30 HP | 600 x 400 mm | 8 mm / 10 mm |

| 4 | PM-GRINDE 800 | 300 to 350 kg/hr | 40 HP | 800 x 600 mm | 8 mm / 10 mm |

| *Output depends upon type of materials, thickness etc. | |||||

| *Above specification of drive are for general purpose applications. | |||||

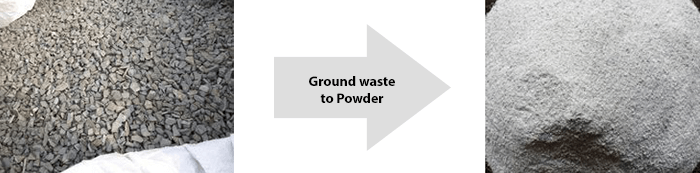

Pulverizer

Better In Pulverizing Technology

Lately as the demand for powder of plastics has increased, pulverizing being the solution for that. Plastech offers improved technology in size reduction of plastics via pulverize machine.

Application

Plastech has designed specially to pulverize semi rigid, brittle and impact resistance materials as and when a powdered product is required

Granulated plastic materials are fed via vibratory feeder into the mill

High speed mill grinds the materials while the suction system draws the materials from mill

With the help of proper metering and various screening system desired powder quality to be achieved. Coarse materials from the screen are re-entering into the mill via closed-loop system

Typical applications are the pulverizing of LDPE, LLDPE, RPVC, HDPE, UPVC, PC and various other plastics

Salient Features

- Sturdy design

- High output with low power consumption. Microprocessor based control system

- Grinding disc of special materials for longer life. Easy to operate

- Less manpower required

- Improved fine materials according to application of plasticizing. Easy to change vibro screen for various powder quality

- Compact design and minimum space utilization

Pulverize Mills for PVC scrap

| Specification | Models | ||||||

| PM-60 | PM-80 | PM-100 | PM-120 | PM-150 | PM-200 | PM-300 | |

| Disc Diameter | 300 | 300 | 300 | 400 | 400 | 600 | 600 |

| Drive kW | 11.5 | 15 | 22.5 | 30 | 37.5 | 56 | 75 |

| Output in kg/hr. | 60 | 80-90 | 100-120 | 140-160 | 170-200 | 250-300 | 350-450 |

| Output depends upon type of materials & cooling temperature | |||||||

Complete Integrated Solution for Waste Shredding, Grinding & Pulverising