Automation for Pipe Extrusion Lines

Debagging

Plastech offers a solution for managing and unloading the Big-Bags by lift crane.

The stations are DBB designed. Big bags up to 2000 mm height and 1100 x 1100 mm side van be effortlessly accommodated.

On demand, the systems of emptying big bags can also be supplied for installation in ATEX area.

Pneumatic Conveying

Dilute Phase

The dilute phase is used in pneumatic conveying of bulk materials.

This system is defined as the flow of material in suspension or transport in flight because the particles are maintained in suspended air along the pipe.

The flow rates of can reach up to 30 tons/h, while the speed of conveying are in the order of 20-30 m/s.

Dense Phase

The Dense Phase pneumatic conveying systems proposed by Plastech are born from specific experiences in the pneumatic transport at low speed.

The Dense Phase conveying systems are particularly suited to handle bulk products like granules, powders and re-ground. The flow rates of transport can reach up to 100 tons/h while the speed of conveying are in the order 5-10 m/s.

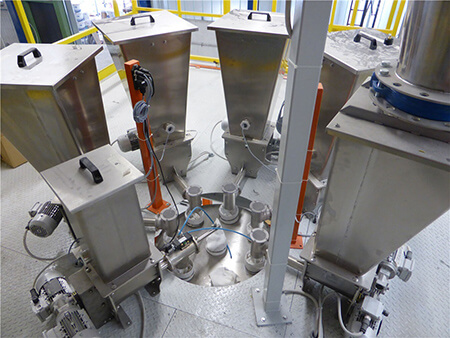

Weighing Hopper

Plastech proposes a solution of WHL (weighing hopper loader) for feed mixing or storage plant where they convey pneumatically and dose various products.

The system is realized by weighing a cyclone filter in combination with a multi valves fitting that selects the different lines of the respective products.

The high Plastech experience developed in the field of weighing and conveying allows systems of up to 7-8 tons/h with very high accuracy in dosing.

Storage Silos

The storage silos are a fundamental element in the structure of a plant as they determine the volume available both for the storage of raw material and storage of finished products.

The choice of the silo thus depends on the required volumes and the type of product to be stored.

For the storage of bulk materials, Plastech offers a large range of solutions:

- Aluminium Silos

- Stainless Steel Silos

- Carbon Steel Silos

- Trevira Textile Silos

Dosing Unit

Plastech offers a full range of dosing units for powders with flow rates from a few grams per minute up to 8 tons/h. Thanks to the special design, the dosing unit Plastech are particularly performing in the extraction and dosing of each type of dust, even less flowing and packing. The feeder offered by Plastech are configured according to the product and customer specifications, and are divided into two families:

- Single Screw

- Double Screw