Side Sealing and Cutting Machine (Automatic)

Side Seal Bag Making Machine

Plastech supply Automatic high-speed bag making machines designed and manufactured in South Korea for high efficiency.

The side seal bag making machine with its high dimensional accuracy delivers up to 210 bags/minute and is suitable for LDPE/HDPE/PP/BOPP films.

Various attachments are available for this machine to meet the demand of a variety of bags like handle punch, pre-sealer, bottom gusset, inside/outside lip former, lateral sealer, perforation, tape applicator for courier bags, web aligner and so on.

Features

½ folding with EPC unwinder

Top folding / Bottom gusset

Ultrasonic Sealing

Bag Shape

Various type of Folding

Full Optional Header Bag

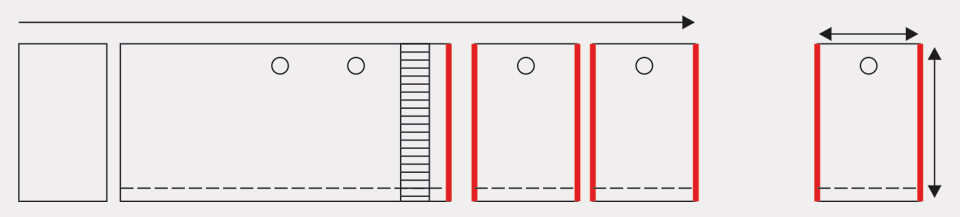

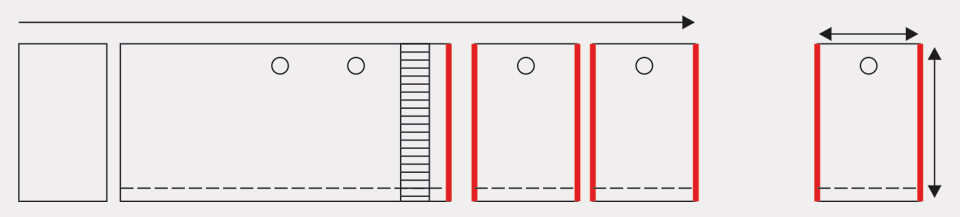

Process

Specifications

| Model | PM – FS 700 (700 mm Feeding Roller) |

| Bag Size | 30~600 mm Width * 600 mm Length |

| Applicable film | OPP, PP, HDPE, PE etc. with 10 ~ 50 mic thickness |

| Capacity | Max. 250 cycles/min |

| Produced Bag | Side sealed Bag with Various type of option |

| *** Design is subject to change According to Customer’s bag shape & size *** | |

Side Seal Bag Making Machine [PM – S 700 (Standard)]

Options

½ folding with EPC unwinder

Top folding / Bottom gusset

Ultrasonic Sealing

Process

Specifications

| Model | PM – S 700 (700 mm Feeding Roller) |

| Bag Size | 30~600 mm Width * 600 mm Length |

| Applicable film | OPP, PP, HDPE, PE etc. with 10 ~ 50 mic thickness |

| Capacity | Max. 250 cycles/min |

| Produced Bag | Side sealed bag with various type of option |

| *** Design is subject to change according to customer’s bag shape & size *** | |

Applications